Aluminum cnc machining price calculator

Demystify Aluminum CNC Machining Costs: In the manufacturing industry, the pricing of aluminum CNC machining often remains a mystery, puzzling countless business owners and procurement

Demystify Aluminum CNC Machining Costs: In the manufacturing industry, the pricing of aluminum CNC machining often remains a mystery, puzzling countless business owners and procurement

# The Ultimate Guide to Aluminum Machining Cost Per Hour (2024 Update) ## Introduction to Aluminum Machining Costs Aluminum remains one of the most commonly

Imagine if a small mistake in your axis CNC milling parts could cost thousands. The CNC milling process needs precision. But how do you ensure it? Precision machining is about more than just machines. It’s about c ombining materials, tolerances, and skills for perfect results. how to find axis cnc milling precision machining parts Every industry, from aerospace to healthcare, needs parts that fit perfectly. This article will guide you on finding axis CNC milling parts that meet your needs. You’ll learn about axis setups, material choices, and picking the right supplier to avoid big mistakes. Key Takeaways Axis configurations expand machining capabilities for complex part geometries. Material selection impacts both cost and long-term part performance. Tolerances must align with industry requirements for safety and functionality. Supplier certifications confirm expertise in the CNC milling process. Clear communication of specifications streamlines the manufacturing process. Understanding Axis CNC Milling Precision Machining Parts Exploring precision machining shows how modern manufacturing makes perfect parts. Let’s dive into the technical basics of these essential components. What Makes a Part “Precision” in CNC Machining Precision machining focuses on tight tolerances, often in microns. Parts need to match exact dimensions and surface finishes. For instance, a medical implant might need ±0.001mm accuracy for safe use. These high-precision machining standards ensure parts work well in tough environments. The Role of Multiple Axes in CNC Milling CNC milling uses axis setups to create complex shapes. Here’s how axes affect production:

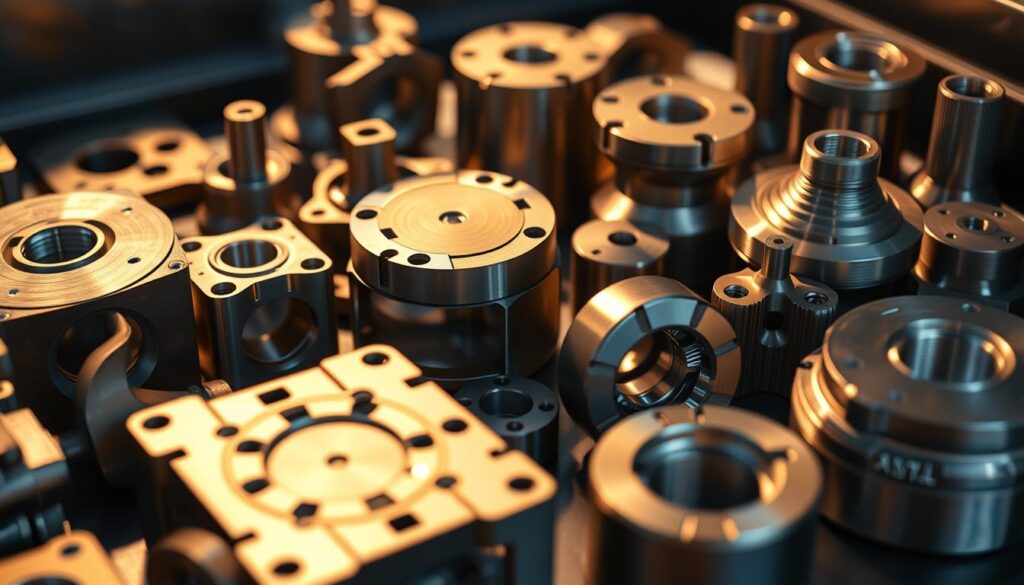

Metal custom-made machining turns raw materials into precise parts. These parts are made to exact specifications, unlike generic ones. Our shop focuses on metal fabrication solutions that are both innovative and reliable. Whether you need a small batch or parts with complex geometry, we’ve got you covered. Our expertise ensures every piece meets your needs perfectly. metal custom-made machining Traditional manufacturing often limits design flexibility. But what if your project needs a part that bends, fits, or performs beyond standard options? Our metal fabrication solutions eliminate guesswork. Our state-of-the-art equipment and skilled engineers turn your ideas into durable, custom components. These components are ready for real-world use. Key Takeaways Custom metal parts offer unmatched design freedom compared to off-the-shelf products. Metal custom-made machining reduces long-term costs by avoiding frequent repairs or replacements. Advanced CNC machinery ensures tighter tolerances and higher accuracy in every fabricated piece. Material choices like aluminum alloys or stainless steel are optimized for each project’s environmental and structural demands. Collaboration with experts streamlines production timelines while maintaining quality standards. The Art of Metal Custom-Made Machining Every metal part is a result of skill and technology. Metal custom-made machining turns raw materials into precise parts. These parts fit perfectly into machines, devices, and structures. It’s a mix of advanced tools and careful craftsmanship, making solutions for specific needs. Understanding Precision Machining Technology Modern precision metal fabrication uses advanced systems like CNC machines. These machines shape metal with incredible accuracy. Key elements include: CAD/CAM software for 3D modeling and simulation Adaptive tooling for diverse material types Real-time quality checks during production The Evolution of Metal Fabrication Techniques Machining has changed a lot, from hand-filed parts to automated systems. Early 20th-century blacksmithing evolved into hydraulic presses and lathes. Today, we have: “Modern metal prototype fabrication reduces development time by 40% compared to traditional methods.” – Industry Trends Report 2023 Computer integration now speeds up design changes. This makes prototyping faster and cheaper. Why Customization Matters in Metal Parts

a highly detailed, photorealistic image of a custom aluminum CNC machining workshop. The foreground depicts a state-of-the-art CNC machine in operation, meticulously crafting a complex

Get a CNC Quote Online – Quick & Easy Pricing Getting a CNC quote online is now easier than ever. Websites like https://wxrapidcert.com/ make it

Custom-made CNC machining parts are key in many industries. They bring more precision, durability, and performance. Choosing top CNC machining services means getting the best manufacturing solutions. Custom CNC

In the world of manufacturing, precision and customization are paramount. Custom CNC machining parts have become an essential component in various industries, from aerospace to

Comparing CNC Machining and Sand Casting Explore the differences between CNC machining and sand casting for manufacturing needs. Features CNC machining sand casting Precision and

Imagine creating parts so precise that even the smallest error could disrupt an entire system. This is the power of precision machining. It’s a process

CNC machining service is a manufacturing process where computer-controlled machines create precise parts. These machines follow programmed instructions to cut, shape, or drill materials like

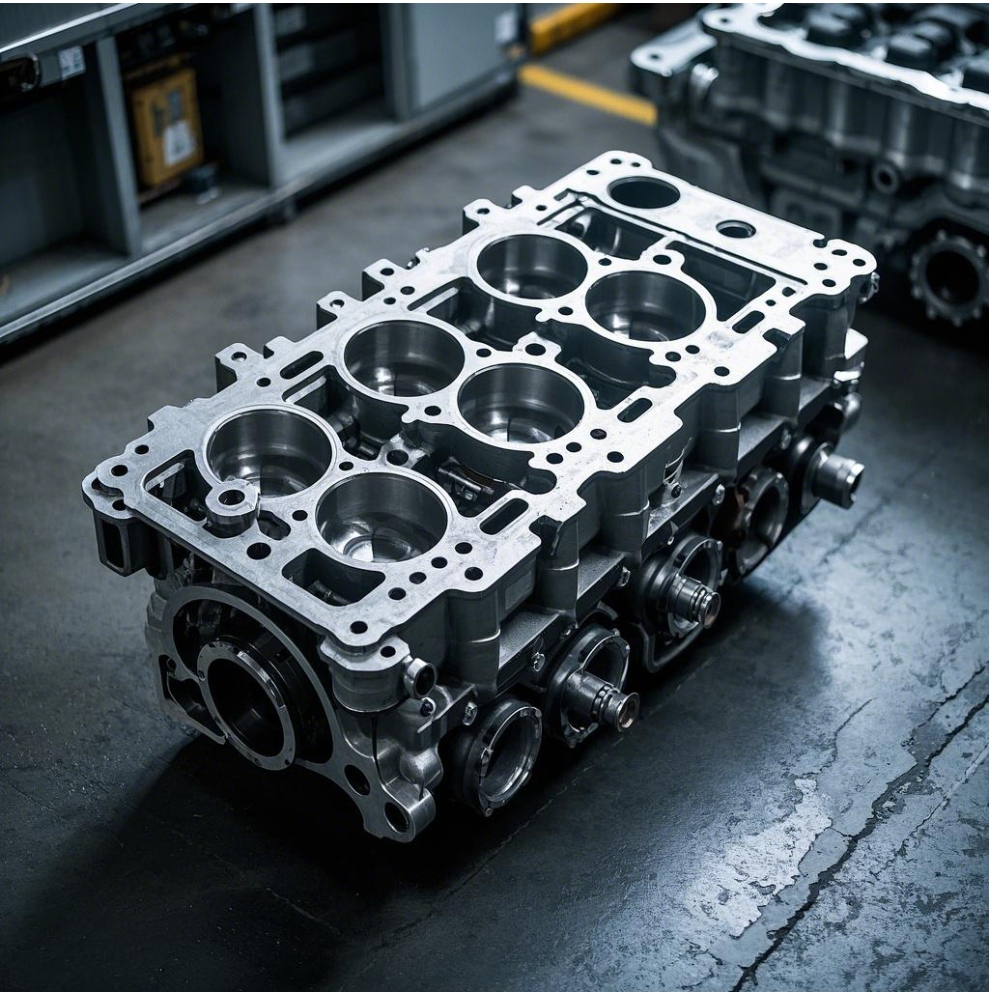

Image Source: pexels CNC machining services have transformed automotive manufacturing by delivering unmatched precision and efficiency. These machines achieve tolerances as tight as ±0.001 inches, ensuring every

Why CNC Machining is Vital for Modern Prototyping and Manufacturing CNC machining plays a critical role in modern manufacturing. It delivers unmatched precision and consistency,

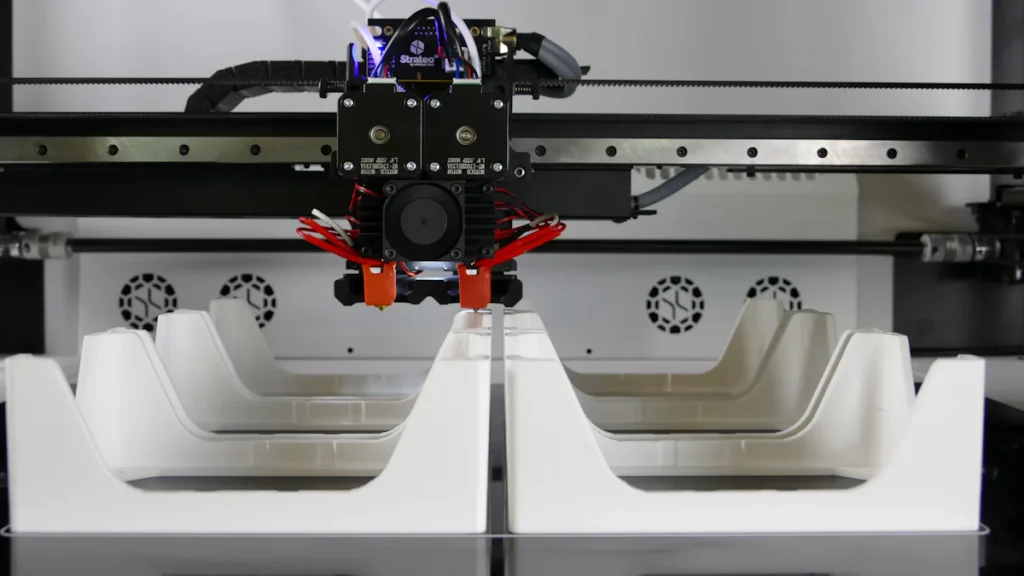

Combining 3D sand printing with CNC machining creates a powerful synergy in precision manufacturing. You can leverage the rapid prototyping and design flexibility of 3D sand printing

Rapid Prototyping of Automotive Powertrain: Technological Innovation and Industrial Promotion In the era of great transformation when the global automotive industry is undergoing energy