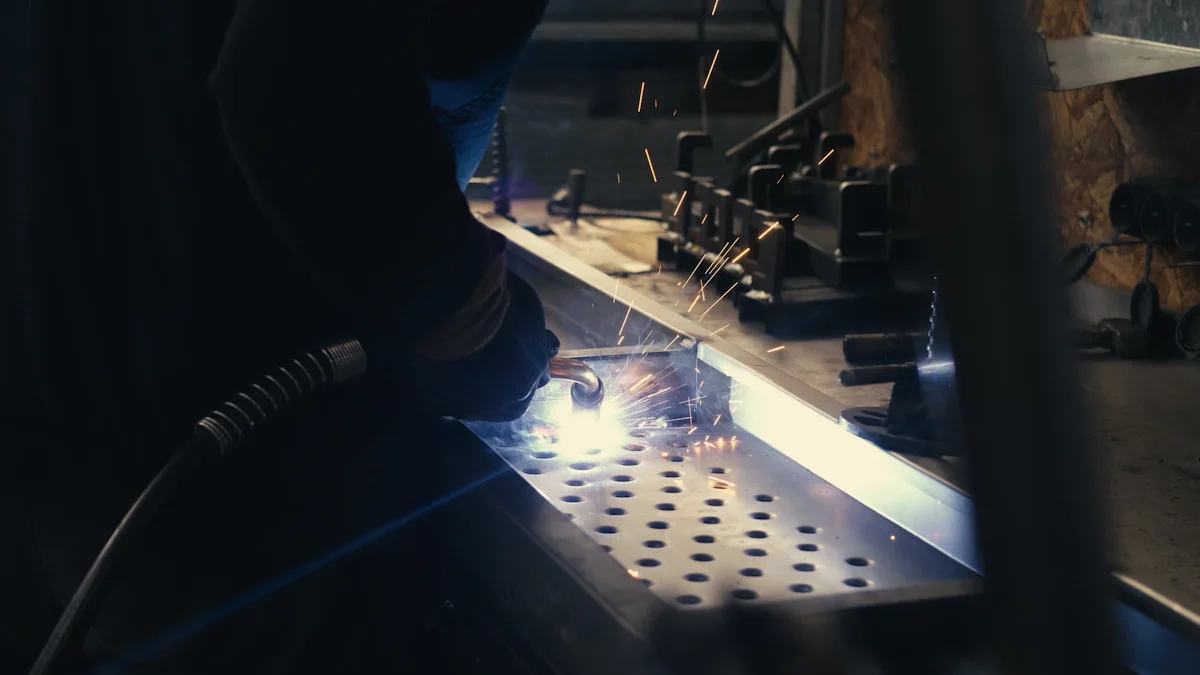

CNC machining service is a manufacturing process where computer-controlled machines create precise parts. These machines follow programmed instructions to cut, shape, or drill materials like aluminum alloys, plastics, and composites. This method ensures high accuracy and uniformity, even for complex metal part machining.

You benefit from CNC machining’s speed and efficiency. Automated systems reduce human error and material waste, making it a cost-effective choice. The process also supports rapid prototyping and large-scale production, helping businesses meet tight deadlines. Its enclosed design enhances worker safety, minimizing risks during operation.

Key Takeaways

- CNC machining is very accurate, great for making detailed parts.

- Its automation makes work faster, running nonstop with quick results.

- It works well for small models or big batches, keeping quality high.

- Picking a good CNC service is important; check their skills and quality.

- CNC machining saves materials and money, making it a smart, eco-friendly choice.

How CNC Machining Service Works

Overview of the Process

Computer-controlled machining explained

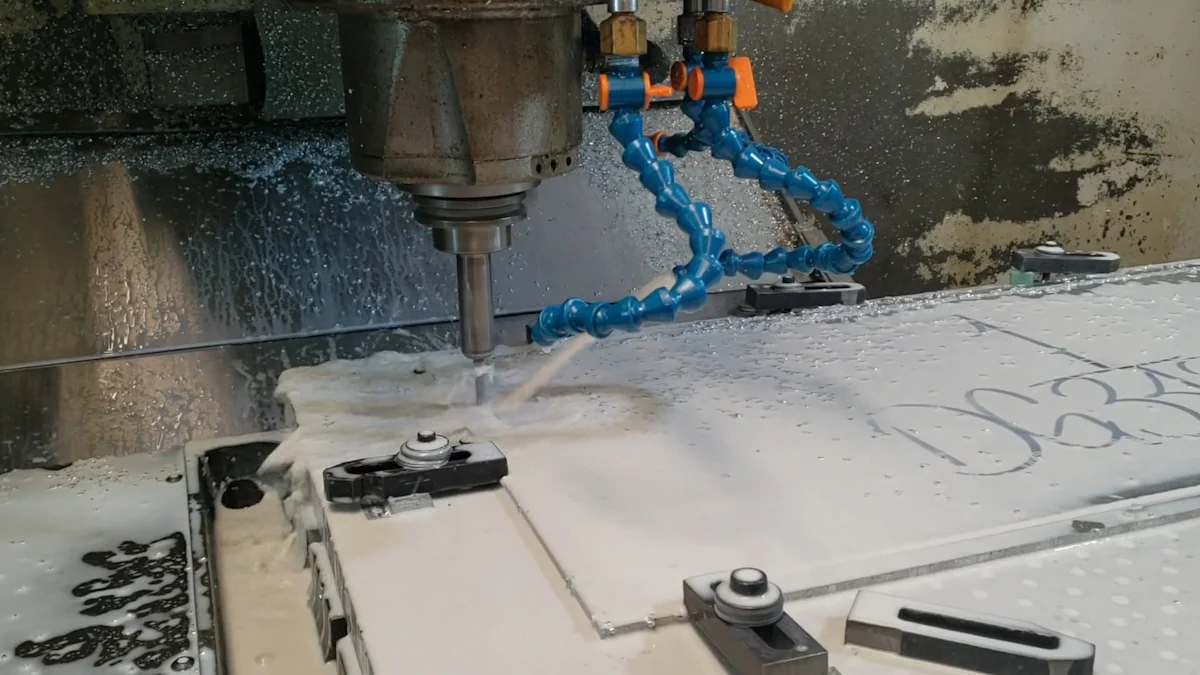

CNC machining service relies on computer-controlled systems to create precise parts. These systems interpret digital instructions, known as G-code, to guide the machine’s movements. This technology eliminates manual intervention, ensuring consistent results. You can use CNC machines to produce intricate designs, such as complex metal parts or aluminum alloy components, with exceptional accuracy. The automation also reduces errors, making it ideal for industries requiring high precision.

Key steps: design, programming, and machining

The CNC machining process follows a structured workflow to ensure precision manufacturing. Here’s how it works:

- Define: Identify the product’s purpose and functionality.

- Feasibility: Assess whether the technology can fabricate the product.

- Develop: Use CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing) software to create and refine prototypes.

- Validate: Check if each component meets design specifications.

- Implement: Execute the machining process to produce the final product.

- Evaluate: Review the product’s performance for potential improvements.

Each step contributes to the creation of high-quality parts, whether for rapid prototyping or large-scale production.

Key Components of CNC Machines

CNC controller

The CNC controller acts as the brain of the machine. It processes programs, coordinates movements, and ensures precision. With its advanced capabilities, the controller allows you to produce user-defined geometries and intricate designs. It also automates tasks like monitoring production sequences, enhancing efficiency. This feature makes CNC machining service a reliable choice for creating complex components, such as medical implants or custom prototypes.

Cutting tools and spindles

Cutting tools and spindles are essential for shaping materials. The spindle rotates the cutting tool at high speeds, enabling it to cut, drill, or mill with precision. High-performance cutting tools, often made from advanced materials like carbide or diamond coatings, ensure tighter tolerances and faster production times. These tools are crucial for machining hard materials, such as titanium or steel, used in industries like aerospace and automotive.

Workholding devices

Workholding devices secure the material during machining. These include clamps, vises, and chucks, which prevent movement and ensure stability. Proper workholding is vital for achieving consistent results, especially when machining intricate designs or working with delicate materials like composites. By keeping the material steady, these devices help you maintain accuracy throughout the process.

Benefits of CNC Machining Service

Precision

High accuracy and consistency in parts

CNC machining service delivers unmatched precision. The machines operate under precise computer control, ensuring each part matches the digital design with incredible accuracy. This process minimizes human error, making it ideal for creating parts with tight tolerances. For example, CNC machines can achieve tolerances as small as 0.001 inches (0.025mm), which is critical for industries like aerospace and medical manufacturing.

You can rely on CNC machining to produce identical parts consistently, whether you need a single prototype or a large batch. The automated system follows a digital template, performing flawless repetitive actions. Additionally, in-process measurement and quality assurance ensure that every component meets exact specifications. This level of precision is essential for complex metal part machining, such as aluminum alloy components or medical implants.

Efficiency

Faster production compared to manual methods

CNC machining service significantly boosts production speed. The automation allows machines to run continuously with minimal human intervention, even enabling “lights-out” manufacturing. Once programmed, CNC machines can produce unlimited identical parts without requiring constant supervision. For instance, a batch of 100 complex parts might take a skilled operator 50 hours using manual methods. A CNC machine can complete the same job in under 17 hours, saving you valuable time.

The efficiency extends beyond speed. CNC machines can position tools and execute cuts with remarkable accuracy, reducing the need for rework. A single CNC machinist can oversee multiple machines, each producing parts at a higher rate than manual methods. This streamlined process ensures faster turnaround times, helping you meet tight deadlines without compromising quality.

Scalability

Suitable for both small and large production volumes

CNC machining service adapts seamlessly to your production needs. Whether you require a single prototype or thousands of parts, the process remains efficient and cost-effective. The digital programming ensures that each part, regardless of quantity, maintains the same high level of precision. This scalability makes CNC machining ideal for industries like automotive and electronics, where production demands can vary widely.

You can also benefit from the flexibility of CNC machining when working with diverse materials, such as aluminum alloys, plastics, or composites. The ability to handle both small and large production volumes ensures that your manufacturing process remains efficient, no matter the project size. This versatility supports rapid prototyping as well as mass production, giving you the tools to innovate and grow your business.

Cost-effectiveness

Reduced material waste and labor costs

CNC machining service offers significant cost-saving advantages by optimizing both material usage and labor efficiency. You can rely on this technology to minimize waste and reduce expenses, making it a smart choice for manufacturing.

- Material Efficiency: CNC machines execute precise cuts, ensuring minimal material waste. Advanced CAD and CAM software calculate efficient cutting paths, allowing you to maximize material utilization. This is especially beneficial when working with expensive materials like titanium or aluminum alloys. By reducing scrap, you save money on raw materials and contribute to sustainable manufacturing practices.

- Labor Savings: Automation in CNC machining reduces the need for manual labor. A single operator can oversee multiple machines, which lowers labor costs while maintaining high productivity. The precision of CNC machines also minimizes human error, reducing the need for costly rework. This efficiency allows you to allocate resources to other critical areas of your business.

- Sustainability: CNC machining supports eco-friendly practices. The technology consumes less energy compared to traditional methods, using about one-seventh of the energy. This not only lowers your production costs but also reduces your environmental impact. Additionally, the reduced waste and efficient material usage align with sustainable manufacturing goals.

By choosing CNC machining, you gain a cost-effective solution for producing complex metal parts, rapid prototyping, or large-scale production. The combination of reduced material waste, lower labor costs, and sustainable practices ensures that your manufacturing process remains both economical and environmentally responsible.

Applications of CNC Machining Service

Industries That Use CNC Machining

CNC machining plays a vital role in several industries, enabling the production of precise and complex components. Here’s how different sectors benefit from this technology:

| Industry | Application |

|---|---|

| Aerospace | Producing products that meet high industry standards. |

| Automotive | Manufacturing parts like engine blocks, transmission components, and brake discs. |

| Medical Devices | Creating complex components such as implants and surgical instruments. |

| Military & Defense | Producing weapons, ammunition, and military vehicles with precise specifications. |

| Industrial Machinery | Manufacturing machinery for food and beverage packaging and material handling systems. |

| Energy | Producing parts for wind turbines and solar panels. |

| Marine | Ensuring performance and safety of vessels. |

| Agriculture | Making components for farm machinery. |

| Consumer Goods | Manufacturing products like electronics and appliances. |

| Electronics | Producing intricate designs and components for various electronic devices. |

You’ll find CNC machining indispensable for its precision and efficiency. It enables the creation of intricate designs and ensures components meet stringent industry standards.

Examples of Products Made

CNC machining service supports the production of a wide range of products across industries. Some notable examples include:

- Automotive Parts: Engine blocks, transmission gears, and brake system components. These parts require high precision to ensure vehicle safety and performance.

- Aerospace Components: Turbine blades, landing gear parts, and engine mounts. Lightweight materials like aluminum alloys are often used to enhance fuel efficiency.

- Medical Devices: Surgical instruments, implants, and prosthetics. CNC machining ensures strict tolerances and customization for patient-specific needs.

- Electronics Items: Printed circuit boards, heat sinks, and connectors. These intricate designs demand exceptional accuracy.

- Energy Sector Parts: Turbine components, pump bodies, and heat exchangers. These products must withstand extreme conditions while maintaining efficiency.

Whether you need complex metal part machining, rapid prototyping, or custom aluminum alloy components, CNC machining delivers unmatched precision and reliability.

Materials Used in CNC Machining Service

CNC machining service supports a wide range of materials, each offering unique properties that suit specific applications. The choice of material impacts the performance, durability, and cost of the final product. Below, you’ll find an overview of the most commonly used materials in CNC machining.

Metals

Aluminum, steel, titanium, and brass

Metals are the backbone of CNC machining due to their strength, versatility, and machinability. Here are some commonly used options:

- Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for automotive, aerospace, and healthcare applications. Its quick machinability makes it perfect for rapid prototyping and complex metal part machining.

- Steel: Alloy steel offers high strength and weldability, making it suitable for gears and shafts. Stainless steel provides excellent corrosion resistance, often used in medical devices and outdoor components.

- Titanium: Known for its high strength-to-weight ratio and biocompatibility, titanium is widely used in aerospace and medical implants.

- Brass: This material combines strength and conductivity, making it a popular choice for electrical hardware and medical equipment.

Plastics

ABS, polycarbonate, and nylon

Plastics offer flexibility and cost-efficiency for CNC machining. They are lightweight and resistant to corrosion, making them suitable for various industries:

- ABS: Known for its toughness and impact resistance, ABS is often used in consumer goods and automotive parts.

- Polycarbonate (PC): This material provides high-impact resistance and stiffness, making it ideal for electronics and protective equipment.

- Nylon: With good elasticity and wear resistance, nylon is commonly used for bearings, insulators, and gears.

Composites

Carbon fiber and fiberglass

Composites like carbon fiber and fiberglass are excellent for creating lightweight yet durable components. These materials are often used in industries requiring high precision and strength:

- Carbon Fiber Reinforced Plastics (CFRP): Aerospace manufacturers use CFRP for wing assemblies and fuselage elements due to its strength and low weight.

- Glass Fiber Reinforced Plastics (GFRP): GFRP is cost-effective and widely used in construction panels, automotive parts, and reinforcement bars.

When machining composites, you must use specialized tools like diamond-coated cutters to prevent damage such as delamination or fiber pull-out. Proper tooling ensures the final product meets your exact specifications.

By selecting the right material, you can optimize the performance, durability, and cost-effectiveness of your CNC-machined parts, whether for rapid prototyping or large-scale production.

Choosing the Right CNC Machining Service Provider

Factors to Consider

Experience and expertise

When selecting a CNC machining service provider, prioritize their experience and expertise. A skilled provider ensures high-quality results, especially for complex metal part machining or aluminum alloy components. Look for a team with a proven track record in handling diverse projects. Their ability to manage intricate designs and tight tolerances reflects their competence. Experienced providers also adapt quickly to challenges, ensuring your project stays on track.

Range of services offered

Evaluate the range of services the provider offers. A versatile provider can handle various materials, from metals like titanium and steel to plastics and composites. This flexibility is essential for unique project requirements, such as rapid prototyping or large-scale production. Providers offering customization and advanced capabilities, like 5-axis machining, can meet your specific needs efficiently.

Quality assurance processes

Quality assurance is critical in CNC machining. Reliable providers implement robust quality control measures, such as precision inspections and statistical process control. These processes ensure every part meets your specifications. Look for providers using state-of-the-art equipment and maintaining detailed documentation for traceability. Skilled personnel and continuous improvement practices further enhance the quality of their services.

Tip: Always choose a provider with a strong commitment to quality assurance. This ensures consistent results and minimizes production errors.

Questions to Ask

What materials and tolerances can you handle?

Ask about the materials the provider works with and the tolerances they can achieve. Providers capable of machining aluminum alloys, titanium, or composites demonstrate versatility. Tight tolerances, such as 0.001 inches, are crucial for industries like aerospace and medical manufacturing.

What is your turnaround time?

Inquire about lead times for your project. Simple parts may take a few hours, while complex components might require weeks. Providers offering rapid prototyping or expedited services can help you meet tight deadlines without compromising quality.

Do you offer prototyping and mass production?

Confirm if the provider supports both prototyping and mass production. This flexibility allows you to test designs before committing to large-scale manufacturing. Providers excelling in both areas ensure a seamless transition from prototype to final product.

Note: Asking these questions helps you assess the provider’s capabilities and ensures they align with your project requirements.

CNC machining service offers unmatched precision, efficiency, and versatility. You can rely on it to produce intricate designs with high accuracy, reduce production time through automation, and customize components to meet specific needs. This technology minimizes human error and handles complex geometries that traditional methods cannot achieve. Future advancements, like AI and IoT integration, promise even smarter manufacturing processes and sustainable innovations.

Explore CNC machining services to elevate your manufacturing capabilities. Whether you need rapid prototyping, complex metal part machining, or custom aluminum alloy components, this technology ensures consistent quality and reliability.

FAQ

What is the typical lead time for CNC machining services?

Lead times depend on the complexity of your project. Simple aluminum alloy components may take a few days, while intricate designs like complex metal parts could require up to two weeks. Providers offering rapid prototyping can deliver faster results.

Can CNC machines handle custom designs?

Yes, CNC machines excel at custom designs. You can create intricate geometries and unique features using CAD software. This capability makes CNC machining ideal for producing complex metal parts, custom prototypes, and aluminum alloy components tailored to your needs.

What tolerances can CNC machining achieve?

CNC machining achieves tight tolerances, often as precise as ±0.001 inches. This level of accuracy ensures high-quality results for applications like medical implants, aerospace components, and rapid prototyping. Always confirm the provider’s tolerance capabilities for your specific project.

Is CNC machining suitable for small production runs?

Yes, CNC machining adapts well to small production runs. Its digital programming ensures consistent quality, even for limited quantities. This flexibility makes it perfect for rapid prototyping or producing a few custom aluminum alloy parts before scaling up.

What materials work best for CNC machining?

CNC machining supports a wide range of materials. Metals like aluminum, steel, and titanium offer strength and durability. Plastics such as ABS and polycarbonate provide lightweight options. Composites like carbon fiber are excellent for lightweight, high-strength applications. Your choice depends on your project’s requirements.